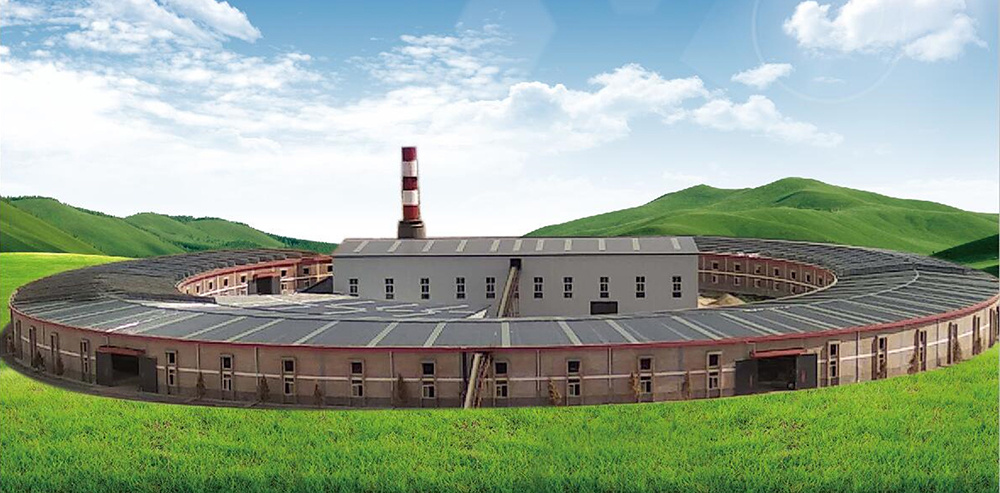

Henan Yaxin Kiln Co., Ltd.

Contact Us

E-mail:

Phone:

Address:

Suixian Industrial Agglomeration Zone, Henan Province

17.1 m cross-section mobile tunnel kiln produces 500,000 - 600,000 sintered clay bricks per day

7.2m cross-section mobile tunnel kiln produces 100,000 sintered clay bricks per day

10.8m cross-section mobile tunnel kiln produces 300,000 sintered clay bricks per day

Pusher Kiln for Powder Metallurgy: Dense Sintering, Precise Dimensional Control, Batch Consistency

8.6m cross-section mobile tunnel kiln produces 200,000 sintered clay bricks per day

Tunnel Kiln for Metal Powder Sintering: High-Density Output, Uniform Structure, Energy Efficiency

12.98m cross-section mobile tunnel kiln produces 400,000 sintered clay bricks per day