Henan Yaxin Kiln Co., Ltd.

Contact Us

E-mail:

Phone:

Address:

Suixian Industrial Agglomeration Zone, Henan Province

The pusher kiln, also known as the push plate furnace or push plate tunnel kiln, is named as the push plate kiln because the heat-resistant plate for placing the sagger is pushed by a hydraulic press.

Read More

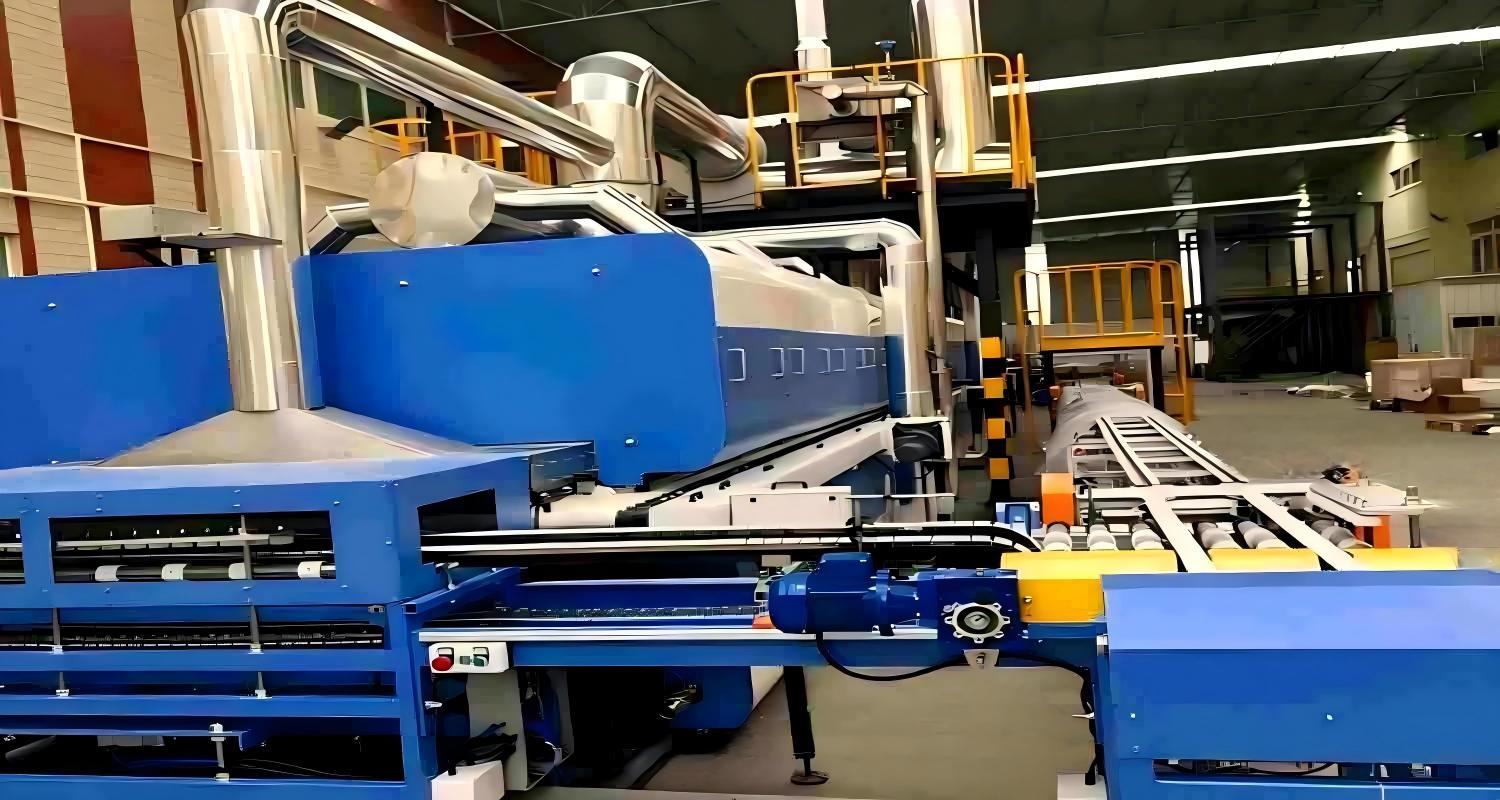

Mobile tunnel kiln is a continuous high-temperature thermal equipment used in brick and tile sintering process. Its core feature lies in the design concept of combining "mobile" and "tunnel". It has the characteristics of low investment, short construction period, reliable equipment quality, stable operation, high production efficiency, low failure rate, energy saving and environmental protection, high yield and low consumption, high degree of automation, and wide range of sinterable raw materials.

Read More

The tunnel kiln is a continuous industrial kiln mainly used for sintering bricks, ceramics, refractory materials and other products. Its structure is in the shape of a long tunnel.

Read More

Classification ofceramics: daily-use ceramics,art (craft) ceramics, industrial ceramics, etc.1. Ceramics for daily use: such as tableware, tea sets, tanks, altars, basins, cans,plates, saucers, bowis, etc.

Read More

The shuttle kiln is an intermittent industrial kiln, named because its kiln car can enter and exit the kiln chamber like a "shuttle". It is widely used in brick, ceramic, refractory and other industries.

Read More

Roller kilns revolutionize domestic ceramics production with continuous transport, cutting energy use by 20-30%, ensuring uniform quality, enabling mass output, and adapting to diverse ceramic types efficiently.

Read More

Roller kilns firing of electronic ceramics enables rapid heat treatment, ensuring temperature uniformity and optimal microstructural development. This ensures consistent dielectric properties, high reliability, and stability in capacitors, substrates, sensors, and actuators.

Read More

Tunnel kiln brick firing: high efficiency, uniform quality, energy saving

Tunnel kiln brick firing ensures high efficiency, uniform product quality, and significant energy savings. Ideal for large-scale production, it offers continuous operation, precise temperature control, and optimized heat recovery, delivering durable sintered bricks with low environmental impact and reduced operating costs.

Read More

Tunnel Kiln for Ceramics: Precise Firing, Consistent Finish, Low Emissions

Tunnel kilns excel in ceramic production, offering precise firing, consistent finishes, and low emissions. Their controlled, continuous process ensures quality while aligning with eco-friendly manufacturing needs.

Read More

Shuttle Kiln for Refractories: High-Temp Resistance, Structural Integrity, Uniform Sintering

Engineered for high-temp resistance and structural integrity, our shuttle kiln ensures uniform sintering of refractory bricks, castables, and monolithic linings. Advanced thermal profiling minimizes cracks while optimizing density. Energy-saving design reduces costs without compromising performance—ideal for precision-fired industrial refractories.

Read More

The pusher kiln is an advanced sintering solution for structural ceramics, delivering precise dimensional control for complex geometries with minimal warping. Its optimized heating profile ensures energy efficiency, reducing operational costs while maintaining consistent performance. Engineered for demanding applications, it provides superior thermal shock resistance, enabling stable processing of high-performance ceramics. Ideal for industrial-scale production, this kiln guarantees reliability, repeatability, and enhanced material properties in structural ceramic manufacturing.

Read More

Tunnel kilns provide an advanced solution for solid waste treatment by delivering efficient volume reduction through high-temperature combustion. Their stable combustion process ensures uniform heat distribution, optimizing energy recovery. Designed for environmental compliance, they incorporate emission control systems (e.g., scrubbers, filters) to meet stringent air quality standards. Ideal for hazardous and municipal waste, tunnel kilns combine operational efficiency with sustainable disposal, supporting circular economy initiatives.

Read More