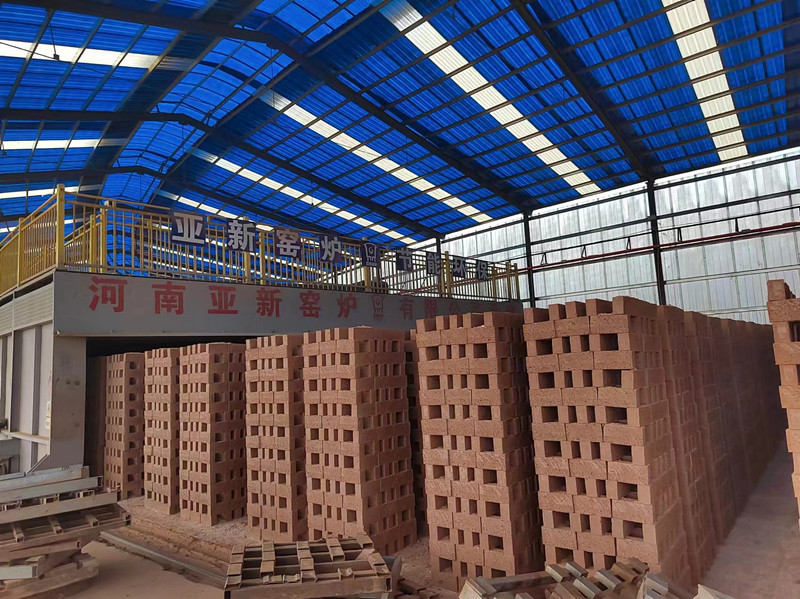

Henan Yaxin Kiln Co., Ltd.

10.8m cross-section mobile tunnel kiln produces 300,000 sintered clay bricks per day

- Commodity name: 10.8m cross-section mobile tunnel kiln produces 300,000 sintered clay bricks per day

Description

Designed for continuous high-volume operation, the kiln system reliably produces an astonishing 300,000 high-quality fired clay bricks per day. It achieves this through optimized thermal efficiency, precise automated control of the firing process, and a seamlessly integrated large brick truck ("mobile kiln") handling system. The kiln is designed for large industrial brick plants that demand the highest output and consistent product quality to meet the needs of large construction projects.

1. High daily output and continuous production

This mobile tunnel kiln has an ultra-large cross-sectional area of 10.8 meters. The continuous firing process ensures stable temperature zones and uninterrupted operation, with a daily output of up to 300,000 sintered clay bricks. This high-capacity design can effectively meet the needs of large projects, shorten production cycles, and improve return on investment.

2. Energy efficiency and environmental performance

The kiln is equipped with an advanced heat recovery system and high-performance insulation materials to minimize heat loss and fuel consumption. It supports a variety of clean fuels (natural gas, liquefied petroleum gas, biomass) and integrates exhaust gas treatment functions to effectively reduce emissions. This ensures compliance with environmental standards while reducing operating costs and carbon footprint.

3. Intelligent control and automation

The kiln uses a PLC-based automation system and HMI interface for precise temperature control and real-time monitoring. Remote diagnostics and data logging functions improve operational reliability, simplify maintenance, ensure consistent product quality, and reduce human errors.

Application

Key words:

Case

Get A Quote

Want an immediate response?

You can consult online or write an email, We deal with your needs immediately

Company Profile

Introduction to Henan Yaxin Kiln Co., Ltd.

Henan Yaxin Kiln Co., Ltd. is a highly professional and innovative enterprise in the field of industrial furnace design, manufacturing and service. The company focuses on providing customers with high-efficiency and environmentally friendly industrial furnace solutions, and its business scope covers the whole process of services from project consulting, engineering design, equipment manufacturing to installation and commissioning and after-sales support.

Company establishment

Patent certificate

Covering national regions

Installation engineer

Advantages

Talent and Professional Advantages

Our company has a team of experienced engineers and technologists who have profound knowledge and practical experience in thermal technology, automation control and energy saving and environmental protection. Through continuous technology development and innovation, the company has obtained a number of national patents and successfully implemented a series of landmark projects, creating significant economic benefits and social value for customers. Moreover, the company owns a number of patented technologies, especially in waste heat recovery, low-NOx combustion, clean energy application and other aspects of the industry leader, to help customers realize green production.

Core Business and Technical Advantages

Energy-saving and environmentally friendly kilns:

such as mobile kilns, roller kilns, tunnel kilns, shuttle kilns, etc., which are widely used in the production of bricks and tiles, ceramics, and refractory materials;

Intelligent control system:

integrated automated temperature control, energy consumption monitoring and remote operation and maintenance technologies to enhance the kiln's operational efficiency.

Market Layout and Service System

Yaxin's kiln business covers the whole country, and actively expand the overseas market, products are exported to Southeast Asia, Africa, the Middle East and other regions. The company adheres to the concept of “customer first” and provides full life cycle services from program design, equipment customization to installation and commissioning, after-sales maintenance, and has successfully provided kiln system integration services for many large enterprises and industrial parks.

Qualification and Social Responsibility

As a benchmark enterprise in furnace industry of Henan Province, Yaxin Furnace has obtained ISO 9001 quality management system certification, high-tech enterprise certification and other qualifications, and participated in the development of a number of industry standards. The company has always been practicing the concept of sustainable development, promoting kiln technology to low-carbon, intelligent upgrading, and providing technical support for the transformation of traditional manufacturing industry.

Related Products

FAQ

undefined